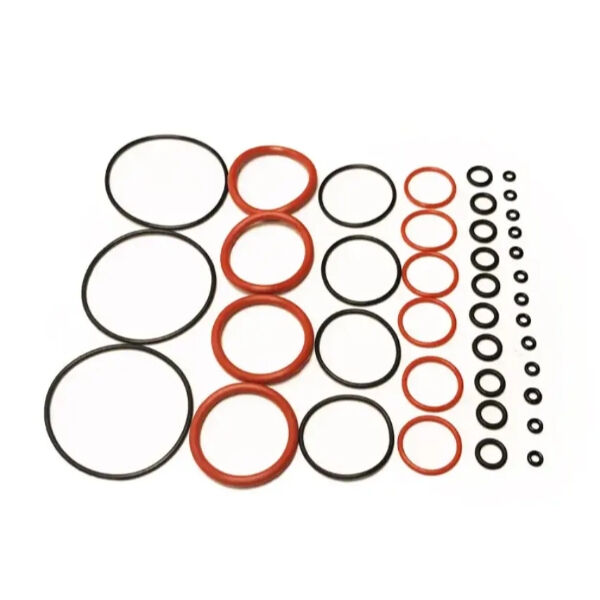

O rings are small round seals that serve a vital individual purpose in preventing leaks of fluids and gases, from escaping machines or vessels. They may be small, but they are very important in keeping to everything working good and churns like nothing else. The most crucial factor is the material used for these O rings to fulfill their purposes effectively. This text will teach you about the reasons why silicone is a very good material to be used for O rings and contribute so nice in our everyday lives.

Silicone is a different type of rubber but, that is out there in our toys, kitchen tools and even some medical products. O ring: The reason this material makes good O rings is because it can be very high temperature tolerant. In other words, this is how silicone allows itself to stay together and not melt or decompose under even when heated heavily by machinery (i.e. engines). Moreover, silicon is resistant to most chemicals so it cannot deteriorate or become damaged as a result of the liquids or gases with which it comes in contact. Silicon O rings are used in so many places because of its great reliability and safety which it provides.

The strength of silicone is also phenomenal. Silicone is a very resilient material, and its durability can withstand the test of time. As a result, silicone O rings frequently have lengthy life spans and do not require to be altered or changed that often in order to last for an extended period without needing any replacement at all.

One of the main advantages that you are going to get out for using silicone made O rings is their make a contribution in well functioning and efficient working machinery. Silicone O rings properly sealed to the machines or containers make it easier for them run smoothly and error free. This is due to the simple fact that there are no leaks or waste and therefore everything was being utilized properly. When every sealing is perfect, it helps in improving the performance of Air Conditioning which improves ductwork and results in longer life equipment.

Add more to that, it is also durable considering the fact they break down or get damaged very slowly. In turn, this means that seals such as silicone O rings will continue to function effectively over many years-good news for anybody with machinery or products which need these kind of tight; powerful rubberized extrusions.

This is possible because Silicone O rings are made of one highly versatile material. This means that, in addition to being durable and malleable, O-rings made from silicone can be formulated to withstand a variety of different environmental conditions. This combination is what makes silicon O rings so useful in different applications.

These silicone O rings are also one of the most versatile ones. They can be placed in countless different locations ranging from factories to hospitals and even at home. The result it is that they are extremely practical and you can count on them to get the job done no matter where they end up being utilized. They ensure that a large number of machines and devices are functioning properly, smoothly.

Our certification under the ISO9001/SGS international quality management system ensures our commitment to top customer service and silicone for o rings Our products are sold on European as well as American markets They comply with strict international standards

We are able to create custom-designed and highly accurate silicone for o rings products by using our cutting-edge molding capabilities. We utilize sophisticated design techniques and tools to transform concepts from customers into tangible products that conform to exact specifications across various sectors including medical, electronics, automotive, and more.

We have more than 35 years of silicone for o rings in the rubber industry, and have an impressive amount of technical know-how. We can fully understand the needs of our customers and maintain high-quality standards throughout the production process.

we offer personalised service and solid after-sales support which includes silicone for o rings refunds or replacements in the event of any issue with our products this is a way to build trust with customers and satisfaction this helps us to maintain our status as a leading company in the rubber industry they also aid in our growth