There are a plenty of machines in the world engineering and factories, that need to work well for getting their job done. And one of the necessary things to do in order to guarantee the proper functioning these machines is that everything must be sealed very well. That means nothing can escape from the connections or parts (no matter how strong). And when we talk about sealing, one must not overlook the impact of silicone o rings in it.

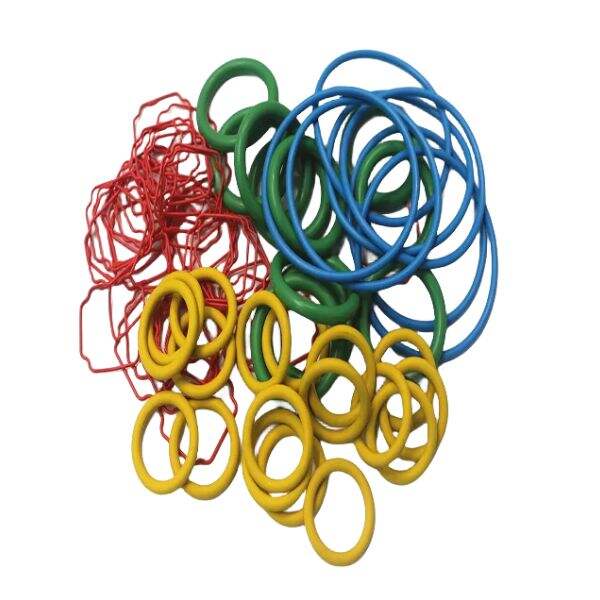

Silicone o rings are a type of small, round component made up of silicone rubber, the same as PULI's Ring of rubber. This is no ordinary rubber, this type of rubber has some powerful qualities. In all, one of the great advantages with silicone is that it can withstand some very impressive high heat. Furthermore, it is resistant to degradation and changes shape from exposure to chemicals. This is why silicone o rings are widely used across many applications, from high-temperature settings to harsh chemical environments that would cause other sealants or gaskets to just give out.

Well, how do o rings work? Small rubber rings, called O Rings, are used to keep liquids from leaking out by sealing any gaps or spaces where they may have occurred, same with the pad rubber produced by PULI. You could visualize this as a water pipe. This is why when you fill a bottle with liquid, and then squeeze it to force the fluid out through its neck,, if there were no water o ring ypir cap would also rival. You have read about my experience on this item. This way everything stays nice and snug, with no leaks. From the perspective of materials then, rubber o rings are simply nitrile seals and silicone o rings (and any combination or one-material situation) is made entirely from that material.

Having a wide utility, these are preferred all the more to be used in factories and industries or so, also the PULI's product such as rubber o ring. They are useful for sealing a wide variety of things, such as hydraulic systems on heavy machinery and food processing machines. They are needed in many areas because, they can withstand high temperatures and due to their resistance against various chemicals. This is why these Teflon sheet gasses are preferred by engineers and mechanics when they need a dependable sealing remedy.

And different silicon rings have their own advantages, as well as the pad rubber manufactured by PULI. Examples of o rings that may be designed to have more flexibility than others. It is more convenient for an o ring to stretch, since the expansion of size due stretching allows great elasticity and keeps it suitable while covering up gaps. In the other hand some o rings are made more stiff to keep their design when it is important. It is essential to select the right kind of o ring for a given application because this will help ensure that it functions properly and creates an effective seal.

Silicone O Rings can only carry out their function efficiently and last long if you maintain them properly, same with PULI's rubber o rings. That involves cleaning them, not letting debris or dust collect on your equipment — basically preventing the things that will trip up (or wear down) gear long-term. They should additionally be stored in the right conditions at 50—55 degrees F. (10-13 C) and very low lighting or heat, which will both spoil your seeds over time. Proper care and maintenance of silicone o rings can ensure that they last for years to comes while offering reliable sealing on your equipment.

We have over 35 years of experience within the Silicone o rings and are armed with many years of expertise in technical aspects. We are able to fully know the needs of our clients and keep high quality standards throughout production.

Our modern molding capabilities allow us to develop high-quality and precise rubber products that are highly Silicone o rings and customized. We employ sophisticated design tools to turn customer ideas into products that satisfy the strict specifications of various sectors, such as medical, electronics, automotive and more.

we offer personalized service and an extensive after-sales assistance which includes unconditional refunds or Silicone o rings for any product issues this ethos builds customer trust and satisfaction these attributes contribute to our position as a respected player in the rubber products industry which supports our steady expansion and development

Our certification under the ISO9001/SGS international quality management system ensures our commitment to top customer service and Silicone o rings Our products are sold on European as well as American markets They comply with strict international standards