If two things must be joined, as in the case of pipes or tanks they should ideally interlock so that nothing leaks out. It is essential if we want everything to function properly, especially with regard to liquids or gases. SOME rubber gaskets are key to preventing things from leaking. Gasket: a thin layer of soft material pressed between two flanges (i. e., A piece of snap-in-place metal ring that forms a face). A flange is a flat metal disc with holes, which attaches to the end of a pipe. It is the rubber gasket that provides a matter seal in between those flanges. Without the gasket, we leak out all sorts of important liquids and gases; which mean damaging equipment or just plain making a mess.

Due to the plethora of various sized and shaped pipes, tanks or other rubbers need like rubber gaskets which are specifically designed for several types. They are created from a form of rubber that is very tough and capable to last for many years before replacement becomes necessary. This is quite significant as we do not want leaks to surface until after a long time may have passed. It is not intended to even so much as deform the gasket with a tight squeeze between two flanges, and if clamped too tightly, it typically comes back out-of-round after unbolting. This is also the reason why rubber gaskets are so great in getting things sealed and not have them leak.

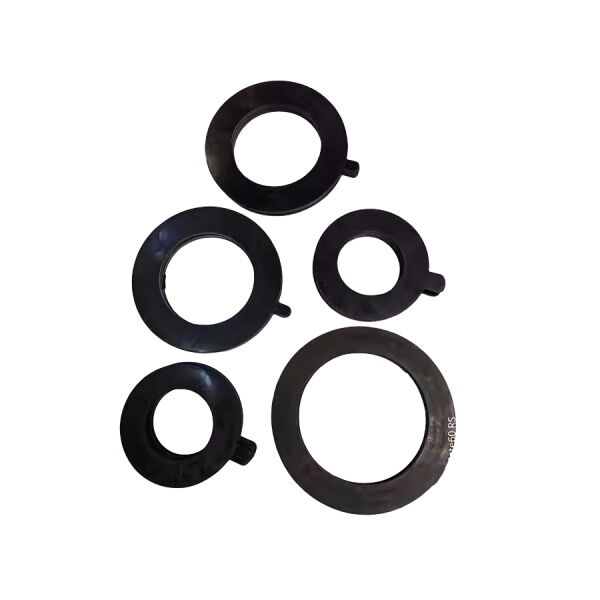

Rubber gaskets come in a variety of sizes and shapes to allow them to be used with various pipes, tanks. There are larger flanges and those can have the shape of free holes, according to pipe opening. Gaskets are created to be placed directly between two flanges, so there will not exist any gaps or places for liquids and gases slide through. This close fit is key to ensuring that nothing moves around and gets damaged. Regardless of the side (or environment) a rubber gasket always grounds in, there is sure to be one that sits between your flanges just how we like it.

Dealing with a rubber gasket in reality takes little time and effort, just like the real world. You have to clean the near portion of them flanges firstly and ensure that if there is any dirt or debris then these can make leaks in future. After that, you set a large rubber gasket between the flanges and bolt them together. It is a simple and quick procedure. If you will ever have to replace the gasket, it can simply be pulled out by getting rid of bolts and eliminating outdated gaskets. Staying on top of these little things helps avoid leaks or damage and keep everything functioning as it should.

Rubber gaskets are a cost-effective solution with long-term benefits. They cost little to purchase or replace and are effective at preventing leaks. Bringing liquids or gases to flow out can damage equipment, and even endanger nearby people. Repairing broken equipment or even paying for someone to repair it can be costly and time-consuming. The most advantageous One is that the rubber gaskets may help stop this valuable issues taking place in any way.

Our modern molding capabilities allow us to develop high-quality and precise rubber products that are highly rubber gasket for flange and customized. We employ sophisticated design tools to turn customer ideas into products that satisfy the strict specifications of various sectors, such as medical, electronics, automotive and more.

rubber gasket for flange provide personalized service a robust after-sales support and guaranteed refunds or replacements in case of any issues with the product this commitment increases customer satisfaction and trust these attributes help us maintain our reputation as a leader in the rubber industry and support our continued growth

We have been certified by the rubber gasket for flange and ISO9001 international quality management system ensuring our commitment to top quality and continuous improvement in order to satisfy the requirements of our customers Our products are exported into European and American markets They meet stringent international standards

Over rubber gasket for flange years of production of rubber products We have deep understanding of the industry as well as technical expertise. This enables us to comprehend the requirements of customers in depth and to maintain the highest standards throughout the production process.