What is a hydraulic cylinder? Then it is a unique type of machine which uses oil to move and work. One of the biggest hydraulic cylinder parts are O-rings. Oil control rings: These are supposed to prevent oil from running part the cylinder, which is crucial if you want yo machine to work properly.

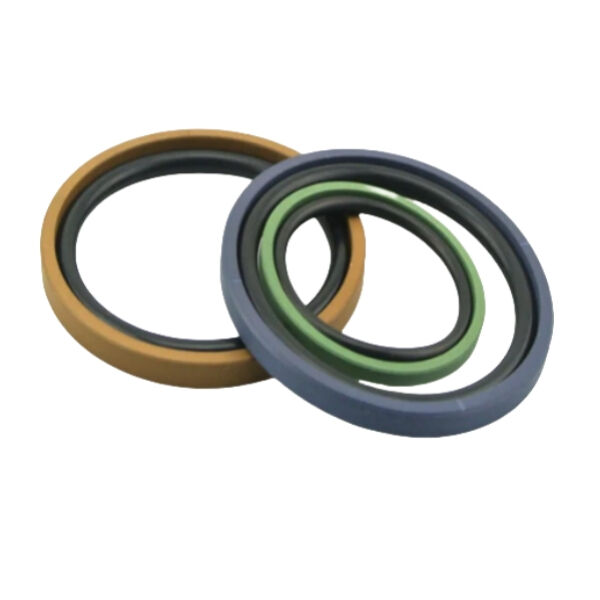

An O-ring is a torus of elastomeric material. It seems quite simple but it has very far reaching impact. O-rings work as seals in hydraulic cylinders. They seal the oil in and keep dirt, etc. out; no O-rings =hydraulic cylinder will not be long-lasting for that machine is most likely to fail due to bad quality of hydraulic seals.

O-rings are critical components for maintaining the operation of hydraulic cylinders. This could indicate that the O-ring of your hydraulic cylinder is damaged. O-rings should be checked and replaced if necessary This will not only prevent leaks but also ensure that everything is operating properly.

Maintenance of the O-ring: It should be washed after each use and some lubricant must applied to it. Take a clean, dry cloth and wipe the dirt or debris that could be on the o-ring. Once you did apply hydraulic oil in the O-ring. This is essential in order to prevent the O-ring from becoming dry and cracked. Check often for any damage, like cracks or frays. If you notice any problems, replace the O-ring immediately. This will avoid leaks and its functioning.

One thing that is relatively easy to adjust are O-rings in a hydraulic cylinder. Remove the hydraulic cylinder from the machine first. Then remove the O-ring from the endcap of cylinder This is at the end of any day, Clean up thoroughly cylinder and remove well before putting a new O-ring. This will help ensure that everything is going to fit properly.

After replacing the new O-ring, apply grease to it using hydraulic oil. This is a crucial step to keep your O-ring supple. Just put hydraulic cylinder back and test if working properly. The O-ring must be put in gently and replaced, making sure to avoid leaks and keep the hydraulic cylinder working condition smooth.

Continuous Swelling — At times, O-rings can continuously swell if they come into contact with very specific chemicals or hydraulic fluids. If they are pumped too large it will harm the cylinder and minimize its capability to get difficult. If the O-ring looks swollen, replace it with an appropriate new one that is compatible with the chemicals or fluids you are using.

We are able to create custom-designed and highly accurate rubber products with our sophisticated molding capabilities. We use sophisticated design tools to transform concepts from customers into products that meet o ring hydraulic cylinder specifications in various industries, including automotive, electronic, medical and many more.

We have been certified by the o ring hydraulic cylinder and ISO9001 international quality management system ensuring our commitment to top quality and continuous improvement in order to satisfy the requirements of our customers Our products are exported into European and American markets They meet stringent international standards

we offer personalized service and an extensive after-sales assistance which includes unconditional refunds or o ring hydraulic cylinder for any product issues this ethos builds customer trust and satisfaction these attributes contribute to our position as a respected player in the rubber products industry which supports our steady expansion and development

We have o ring hydraulic cylinder than 35 years of experience within the rubber industry. We have an impressive amount of technical know-how. This enables us to comprehend the requirements of customers in depth and to maintain the highest standards throughout the production process.