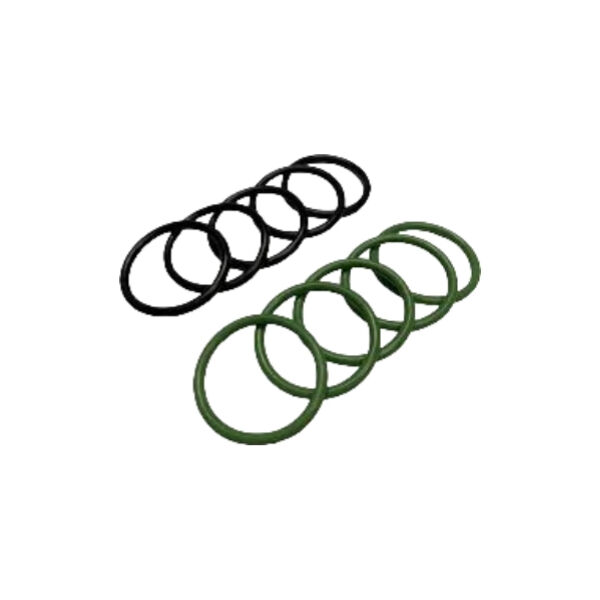

An NBR 70 O Ring is just like a rubber ring but has its own significance in many work places. They may be a little more expensive than some other options, but these rings are forged from Nitrile Butadiene Rubber — an extra-tough type of synthetic rubber. In practical terms, this means that it is not harvested from trees similar to natural rubber but manufactured in a plant with specific attributes allowing use for many applications

The NBR 70 O Ring is a circular ring that allows for assembly of two mating surfaces in such way to avoid high leakages. An O-Ring gets its name because of the shape it is in, which looks like the letter O. It is said that the NBR ring: "NBR" stands for Nitrile Butadiene Rubber, which also tells us what kind of rubber it makes. The 70 is an important number as well, indicating how stiff or soft the rubber compound. A higher number indicates a harder rubber, which changes how it feels and performs in various scenarios.

After that, you have to consider the temperature and pressure conditions in which ring is used. NBR 70 O Rings operate in temperatures between -30 degrees to +120 degree Celsius, so pretty hot! They can further handle pressures of around 1500 psi, and a little more which shows, there being pressure打れ pousses to press. If your job requires that the ring withstands more heat and pressure than this, then you may need to search for a different type of rubber ring (like an EPDM or Viton) applied depend on each circumstance

NBR 70 O Rings are used in a large number of applications and it comes with not only many advantages but also disadvantages. One of the best advantages is their versatility use them in loads and any kind. They are also oil and water resistant within acceptable limits, they could even used at places where there is a little too much of fat or solvent spilled on (mind you i said with in limit) As well, NBR 70 O Rings are usually the most budget-friendly rubber rings as compared with some other similar products — so if you need to buy a lot of them for future use because they have more than enough durability and acceptable cost-performance ratio.

That said, there are also some cons to using NBR 70 O Rings. A risk is that they likely would not do very well in extremely high temperatures or pressures. If you work in something that is very hot or under a lot of pressure, then your ring may not last as long as only one year depending on the environment. A problem with NBR 70 O Rings is that they may not be the most suitable for applications where there's lots of friction and wear (which might cause earlier wearing out)

AS568 NBR 70 O Rings are widely used in most fields and most industry, suitable for a broad range of applications. They are, for instance used as seals in the automotive sector to seal hoses and fittings in cars and trucks. This only leads to leaks and the car not running right. They are also found in the pipe and valve seals, which is important for environmental conditions as well. These rings are present even in many common house-hold items like faucets and shower heads where their function is to avoid leakage and let water pass through)`

Taking Care of Your NBR 70 O Rings To keep your NBR 70 O Rings last longer, it is very important that you take care and maintain this type of material. You MUST keep them clean…. Whipe all the dirt that get stuck in it… That will basically cause the ring to wear out too early, which means that it won't seal properly when you need for most厂of it. It is also a good call to use silicone based grease for greasing up the ring. Flaring the end of one side a little will allow the ring to slide right on and give better sealing.

Over nbr 70 o ring years of production of rubber products We have deep understanding of the industry as well as technical expertise. This enables us to comprehend the requirements of customers in depth and to maintain the highest standards throughout the production process.

we offer personalised service and solid after-sales support which includes nbr 70 o ring refunds or replacements in the event of any issue with our products this is a way to build trust with customers and satisfaction this helps us to maintain our status as a leading company in the rubber industry they also aid in our growth

We are able to nbr 70 o ring and manufacture custom extremely precise rubber products using our sophisticated molding capabilities. We leverage sophisticated design tools and techniques to convert customer ideas into products that meet exact specifications in a variety of industries, including medical, electronics, automotive, and more.

Our certification under the ISO9001/SGS nbr 70 o ring assures our commitment to superior customer service and continual improvement Our products are exported to European and American markets meeting stringent international requirements