It is perfectly normal for you to be a little thrown off when you hear the words "EPDM PTFE gasket"! Here, these terms might sound like a mouthful but both of them are really just different materials for said rubber seals. You should also know that how you can make these O Rings Water Seals other common with his more information will help a lot in different works and industrial places.

EPDM PTFE gaskets find their application in a number of places; from food factories to hospitals, and even chemical plants. This makes them ideal for the majority of machines and tools associated with these industries. In the absence of these gaskets, many machines may experience errors which in turn can result in major disruptions to the entire production unit.

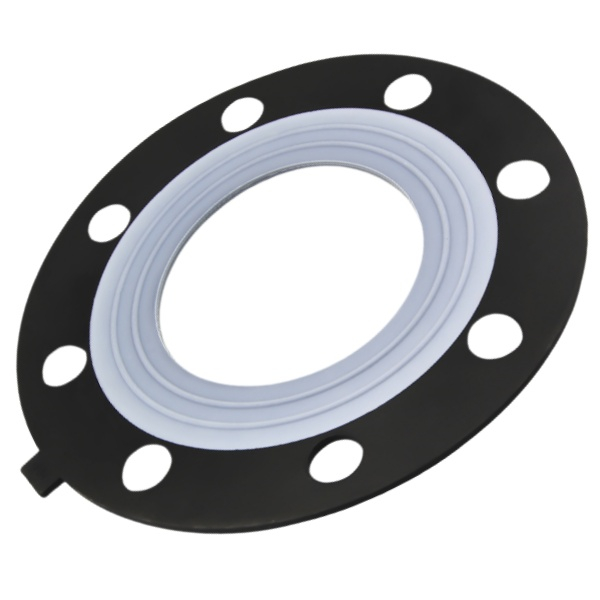

EPDM PTFE gaskets are great because they can withstand really high temperatures and a lot of pressure. This is ideal for extremely high-temperature machines. They are also resistant to chemicals, which means they will not disintegrate or break down when exposed to powerful substances. This is important as factories and plants often used toxic chemicals, well kept seals make it possible for everything to continue running smoothly.

The gaskets here is the combination of a special rubber that has been fortified to withstand incredibly strong chemicals. And that durability matters, as lots of these suckers live in places wherein they can be subjected to the kinds of things that could assail them. Shortages of gaskets might result in leaks, which are a hazard as well as expensive.

4- EPDM PTFE Gaskets are Non Corrosive and Durable! That means you can use the same seals longer without needing to replace it compared to some other types of rubber. You save money on repairs and maintenance as you do not have to replace them often. The benefits to all industries involved are that machines actually end up working better and for longer time periods.

EPDM PTFE gaskets can be used within a variety of industries ranging from foods and beverages up to medicines and chemicals. These are commonly used in machines (pumps, valves etc) and mechanical systems. These gaskets are very important as they seal two components together to prevent them from leaking. They can potentially damage machines and equipment or even endanger people in the area.

Another ideal solution is the use of EPDM PTFE gaskets, which are known to be more durable compared to other sealing materials. Not to mention, they last longer than factory gaskets which can save businesses money in replacement costs. That controls expenses as well as keeps work flowing with fewer interruptions to repair.

Our modern molding capabilities allow us to create epdm ptfe gasket and precise rubber products that are highly precise and customized. We leverage sophisticated design techniques and tools to transform concepts from customers into tangible products that meet precise specifications in a variety of industries, including electronic, automotive, medical and many others.

we offer personalized customer service as well as robust after-sales support including full refunds or replacements on any issue with our products this ethos builds customer trust and ensures their satisfaction these epdm ptfe gasket help us maintain our standing as a pioneer in the field of rubber and support our continued growth

We epdm ptfe gasket over 35 years of experience within the rubber industry. We have a wealth of technical expertise. This enables us to comprehend customer needs thoroughly and maintain high standards throughout production.

Our certification epdm ptfe gasket the SGS/ISO9001 international quality management systems assures our commitment to top customer service and continuous improvement Our products are exported into European and American markets They are in compliance with stringent international standards