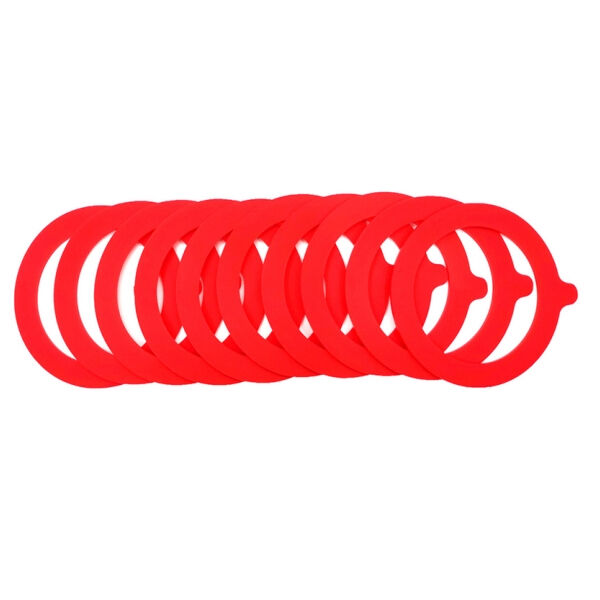

In short, custom silicone gasket is a specialized part to prevent any leaking of machines or equipments. Recall what you can of a hard shell that prevents things from leaking out or entering where they ought not be. Machines will need to function, this is key. This is a soft and flexible silicon-based gasket that means you can construct this into different sizes and forms making it suitable for most machinery applications. This flexibility is what does silicone gaskets so much of use!

Using a custom made silicone gasket is an effective method to save important financial resources in several different ways. Machines with an ineffective seal will have less maintenance longevity. This can cost you tons of money in expensive repairs or even having to go out and buy another machine. Machines are able to perform better for a longer time with the proper gasket. Well, this ensures both saving money and creating lesser waste as there will be less disposal of spoilt machines.

It is also very convenient to be working with a trusted manufacturer that would know the different purposes and applications of custom silicone gaskets. That way, you can have full peace of mind knowing that the gasket was manufactured correctly and will hold up to time as you keep everything secure.

While when manufacturing cars, and other vehicles custom silicone gaskets are very important. Amongst other things, they help to seal the oil pan and also valve cover which are vital for engine performance. Braking fluid will seep if these seals are inconsistent This can lead to damaging the engine components and could end up in hefty repairs.

Medical device gaskets are subject to higher standards than most other applications, not only in terms of precision but also with regard material quality suitable for the human body. So that means the manufacturer if they want to, can only use silicone on you which is approved for medical approval. Patient safety is key, and having the right equipment to help with that really makes a difference.

To recapitulate, bestowing complex machinery to cars and medical gizmos is quite the same; making extra-ordinary quality custom silicone gaskets involves a lot of skilful work. Both the shape and size as well as material are application-specific which is why, the manufacturer has got to learn how9.

In working with a manufacturer that has demonstrated repeated success, businesses can have confidence in the durability and dependability of their gaskets We rarely have any need to replace parts — as a result, higher durability means less wear and tear before the final product needs replacing; thus cheaper cost — overall makes manufacturing better.

Over 35 years of production of rubber products we have deep industry knowledge and technical prowess. We fully be aware of the demands of our clients and ensure high standards of quality custom silicone gasket the process.

custom silicone gasket provide personalized service a robust after-sales support and guaranteed refunds or replacements in case of any issues with the product this commitment increases customer satisfaction and trust these attributes help us maintain our reputation as a leader in the rubber industry and support our continued growth

Our certification under the ISO9001/SGS custom silicone gasket assures our commitment to superior customer service and continual improvement Our products are exported to European and American markets meeting stringent international requirements

We are able to create custom-designed and highly precise rubber products through our advanced molding capabilities. We custom silicone gasket sophisticated design tools to transform concepts from customers into products that are precisely designed for various sectors, such as medical, electronics, automotive and many more.